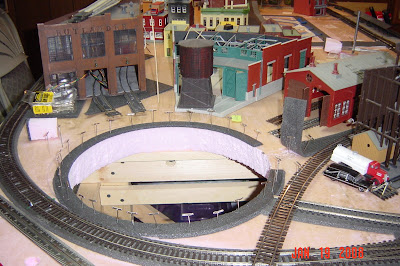

The above photos show some of the changes to the Rutland. Top photo is of the new Walther's Built-up 90 ft. turntable. In a previous post I showed the old turntable salvaged from the last Rutland layout. Never worked well so I bought this one. Totally amazing craftsmanship. It is programmable for 60 stops.

The above photos show some of the changes to the Rutland. Top photo is of the new Walther's Built-up 90 ft. turntable. In a previous post I showed the old turntable salvaged from the last Rutland layout. Never worked well so I bought this one. Totally amazing craftsmanship. It is programmable for 60 stops. The second and third pictures show Depot Park as it becomes populated with grass and trees. The white sticks among the trees and on Center and Washington streets are the locations of the streetlights. The lights have had their electrical connections lengthened and are about ready for installation. The bottom two pictures are of the bank building on the corner of Merchants Row and Center Street. Cannot remember the name of the bank but will research it. Many hours have been spent detailing the interior of the bank. Unfortunately the picture is very blurry but you get the idea. The structure has lights, shades in the windows and interior walls. It looks really good up close. I am not a great photographer but will endeavour to get a better picture of the bank. There are still two storefronts that need to be detailed. That's for another day.